Catalytic combustion equipment is suitable for ambient temperature, high air volume, low to medium concentration, volatile organic compounds (mainly based on actual reports). Waste gas can be treated with organic solvents (mainly based on actual reports), including benzene, ketones, esters, aldehydes, ethers, alkanes, and their mixed gases.

Working principle: First, organic (based on actual reports) exhaust gas is filtered through a dry filter to remove some dust particles. Then, organic (based on actual reports) exhaust gas enters an activated carbon adsorption box for adsorption and purification. The purified clean gas is discharged into the atmosphere through the main exhaust fan. The adsorption device is equipped with a backup adsorption box. When the activated carbon adsorption is saturated, it switches to the catalytic combustion desorption state through a control valve; The desorption system adopts online desorption (or offline desorption), which is a continuous processing process, and the saturated adsorption box is used for the next recovery.

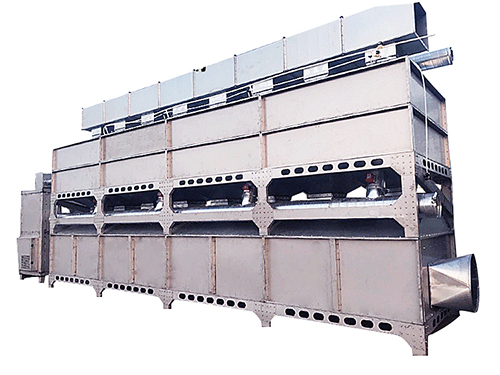

Performance characteristics of catalytic combustion equipment:

1. Metal platinum and palladium plated catalysts are used as honeycomb ceramic carriers, with good purification efficiency, long equipment service life, and low gas flow resistance;

2. Diverse facilities: Fire prevention (mainly based on actual reports) (mainly based on actual reports), dust collectors, pressure relief holes, over temperature alarms and other protective facilities are diverse;

3. Preheat 15- Heat at full power for 30 minutes. When working, only the visible power is consumed. When the concentration of exhaust gas is low, automatic intermittent compensation heating is used;

4. Waste heat can be returned to the drying channel for drying, reducing the power consumption of the original drying channel; It can also be used for the reuse of thermal energy in other aspects of the factory.

Catalytic combustion equipment should be desorbed according to different exhaust gas contents and daily working hours. Usually takes 15-20 days to detach. The detachment time is 3-5 hours. The desorption time of catalytic combustion equipment is mainly determined by the filling amount of activated carbon and the adsorption value of activated carbon. The filling amount of activated carbon is high, the adsorption value is high, and the desorption time interval of catalytic combustion equipment is long, usually 15-20 days. If the adsorption value of the catalytic combustion equipment is low and the amount of activated carbon filling in the equipment is small, the catalytic combustion equipment is prone to saturation. The desorption time of catalytic combustion equipment is generally 3-5 days, which wastes a lot of electricity. Increased usage costs and short lifespan of activated carbon. Good activated carbon is usually replaced every 2-3 years. The activated carbon of catalytic combustion equipment that requires frequent desorption is basically replaced once a year.

Precautions for handling catalytic combustion equipment:

1. The exhaust gas does not contain the following substances; High viscosity grease. Such as phosphorus, bismuth, arsenic, antimony, mercury, lead, tin; High dust concentration;

2. When selecting equipment, the composition, concentration, and outlet temperature of the exhaust gas should be indicated;

3. The equipment installation site is free of corrosive gases and has good rainproof measures;

4. Power supply required for three-phase AC 380V frequency 50Hz equipment;

Scope of application of catalytic combustion equipment:

1. Used for purifying organic solvents such as benzene, alcohols, esters, phenols, ethers, and alkanes (based on actual reports);

2. Organic (based on actual reports) exhaust gas purification is suitable for industries such as enameled wire, machinery, motors, chemicals, instruments, automobiles, engines, plastics, and electrical appliances;

3. Suitable for various drying lines, printing inks, motor insulation treatment, and other drying lines.