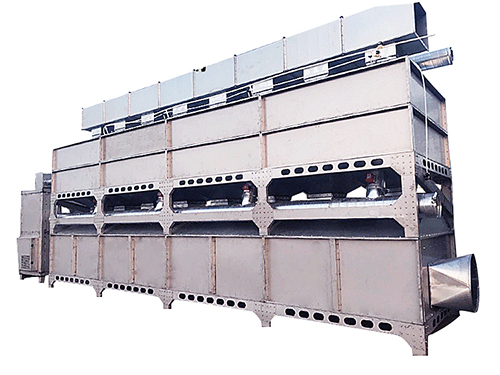

Working principle of stainless steel catalytic combustion device:

The stainless steel catalytic combustion device is designed based on two basic principles: adsorption and catalytic combustion. That is, adsorption concentration catalytic combustion method. When activated carbon is used to adsorb exhaust gas, the speed is suitable. When saturation is reached, the adsorption operation is stopped, and then activated carbon is adsorbed using hot air flow to concentrate the attachments and send them into the catalytic combustion chamber for carbon dioxide and carbon dioxide emissions. When the concentration of exhaust gas exceeds 2000ppm, the exhaust gas in the catalytic bed can remain natural without external heating. The exhaust gas from combustion is partially emitted into the atmosphere, and most of it is sent to the adsorption bed for the desorption of activated carbon.

Characteristics of stainless steel catalytic combustion device:

1. Easy to operate: automatic control during device operation

2. Low energy consumption: The device starts for about 20 minutes and heats up to the catalytic combustion temperature.

3. Equipped with a system, pressure relief system, over temperature alarm system, and automatic control system.

4. Small footprint: Similar products only account for 80%, with no requirements for equipment foundation.

5. Long service life: The replacement time of the catalyst is determined by the processing air volume and exhaust gas concentration.