RTO catalytic combustion equipment requires three stages: adsorption, desorption, and catalytic combustion. The desorption value of activated carbon should be set according to specific values such as workload, working time, and exhaust gas concentration in each industry. When the adsorption of activated carbon reaches saturation, the catalytic combustion system will automatically desorb. When the activated carbon catalytic combustion equipment is desorbed, the air first enters the catalytic combustion chamber through the desorption fan and is heated by the heater of the catalytic combustion chamber. However, when the temperature reaches 200 ℃, it enters the desorption tube through the heat exchanger and is cooled in the mixed flow box of the desorption tube. When the temperature inside the mixed flow box reaches the desorption temperature of activated carbon, it enters the activated carbon adsorption box through a valve to desorb Longtai activated carbon. The exhaust gas enters the desorption channel through the above-mentioned valve, and then enters the catalytic combustion chamber to react with the catalyst. High temperature gases are generated during the reaction process, typically at a temperature of 260-380 ℃. A set of heating tubes is turned off when the temperature reaches 300 ℃. When the temperature reaches 350 ℃, both sets of heating tubes are turned off. When the temperature reaches 380 ℃, all three sets of heating tubes are turned off. After all electric heating is turned off, save power. There is a ceramic heat storage body around the catalyst, which can lock in heat. Catalysts can react without heating for a long time. When the temperature is below 300 ℃, the electric heating starts automatically and begins to heat again. No personnel control is required. Save manpower and energy.

Principle of catalytic combustion in spray paint booth:

According to the two basic principles of adsorption () and catalytic combustion (energy-saving), a dual gas path continuous operation is adopted, with one catalytic combustion chamber and two adsorption beds alternately used. Firstly, use activated carbon to adsorb exhaust gas, and stop adsorption when saturation is reached. Then, use hot air flow to desorb objects from the activated carbon, concentrate the activated carbon (with a concentration several tens of times higher than before), and send it to the catalytic combustion chamber for catalytic combustion into carbon dioxide and water vapor, which are then discharged. When the concentration of exhaust gas exceeds 2000mg/m3, the catalytic bed can maintain spontaneous combustion without external heating. Part of the exhaust gas after combustion is discharged into the atmosphere, and most of it is sent to the adsorption bed for activated carbon. This can meet the heat energy requirements for combustion and adsorption, achieving the goal of energy conservation. The latter can enter the next adsorption; During desorption, another adsorption bed can be used for purification operations, suitable for both continuous and intermittent operations.

Scope of application of RTO catalytic combustion equipment:

Paint, printing, electromechanical, household appliances, shoes, plastics, and various chemical workshop volatile or leaked exhaust gas purification and odor, suitable for low concentration, should not be directly burned or catalytically burned and adsorbed to recover exhaust gas, especially in low concentration treatment scenarios, can achieve satisfactory economic and social benefits.

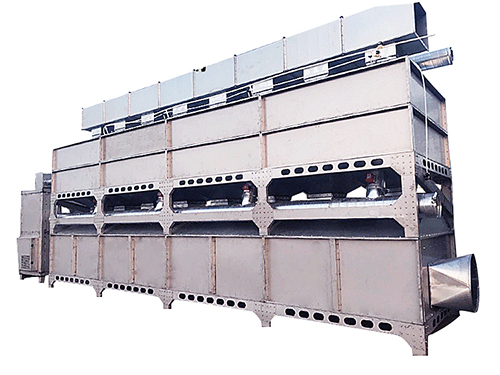

The main features of RTO catalytic combustion equipment are:

The equipment design principle is reasonable, the materials are good, the performance is stable, the structure is simple, energy-saving and labor-saving, and there is no secondary pollution. This device has a small footprint and is lightweight. The adsorption bed adopts a drawer structure, which is easy to fill and replace. Honeycomb ceramic precious metal catalysts are used in catalytic combustion chambers with low resistance.