Catalytic combustion environmental protection equipment mainly oxidizes exhaust gas from chemical air pollutants into carbon dioxide and water under the action of metal catalysts. Adding metal catalysts cannot change the previous chemical equilibrium, so it can only change the efficiency of exothermic reactions, and the characteristics of metal catalysts themselves during the reaction process are not very significant.

Working principle of catalytic combustion environmental protection equipment:

1. To avoid catalyst bed blockage and catalyst poisoning, pre-treatment should be carried out before the exhaust gas enters the bed to remove dust, droplets, and toxic substances in the catalyst. When the exhaust gas contains particulate matter, the particulate matter content is reduced to below 10mg/m2 through a pretreatment process.

2. The preheating device includes an exhaust gas preheating device and a catalyst burner preheating device. Due to the low catalytic activity temperature of the catalyst, catalytic combustion is referred to as the combustion temperature of the catalyst, which brings the temperature of the exhaust gas and bed to the combustion temperature. Therefore, a preheating device is installed. But for high-temperature applications such as paint lines, insulation materials, and paint, the temperature can reach over 300 ℃ without the need for preheating devices.

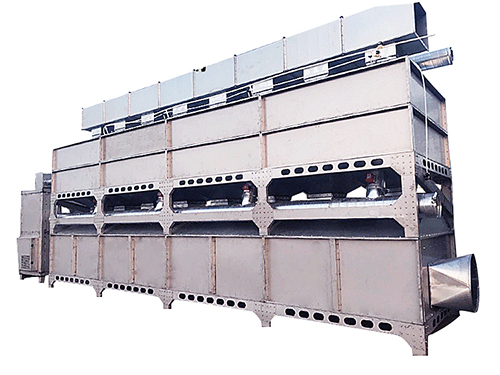

3. Catalytic combustion devices generally use fixed bed catalytic reactors. The design of the reactor should be carried out in accordance with specifications, with easy operation, maintenance, and convenient loading and unloading of catalysts. Catalytic combustion reactors are typically designed as basket or drawer components. In the process of catalytic combustion, components should be designed according to specific circumstances.

4. When the exhaust gas contains corrosive gases (such as sulfur, chlorine, nitrogen and other compounds), the inner wall of the reactor and the main body of the heat exchanger should be made of stainless steel material not less than 316L; Auxiliary desulfurization, chlorine, and nitrogen processes should also be installed after the catalytic reactor to meet exhaust standards.