Catalytic combustion spray painting room exhaust gas treatment

Catalytic combustion spray painting room exhaust gas treatment

The composition of exhaust gas in the paint booth

Spray painting exhaust gas is generated during the spraying process. Liquid coatings form atomized dust particles and volatile triphenyl organic compounds (mainly reported in actual reports) and exhaust gases (mainly reported in actual reports) under the action of air pressure. The particle size is small, the concentration is high, and most of them are below 10 μ m. If not pretreated, the micropores of activated carbon will be blocked at a suitable speed, causing the adsorption of activated carbon to fail.

Characteristics of exhaust gas in paint spraying room:

1. During the painting process, paint particles independently suspended in the exhaust gas;

2. Paint: Water droplets carrying paint particles; Waterborne paint: Water droplets that dissolve paint particles;

3. The raw material odor of the paint itself, the gasification state of the diluent (room temperature paint curing agent), and the odor released during the reaction and curing process.

Spray booth exhaust gas treatment method 1: filtration: adsorption method

Spray painting exhaust gas is generated during the spraying process. Liquid coatings form atomized dust particles and volatile triphenyl organic compounds (mainly reported in actual reports) and exhaust gases (mainly reported in actual reports) under the action of air pressure. The particle size is small, the concentration is high, and most of them are below 10 μ m. If not pretreated, the micropores of activated carbon will be blocked at a suitable speed, causing the adsorption of activated carbon to fail.

After being cleaned by a water curtain cabinet, the spray paint exhaust gas has a good cleaning and degradation effect on the paint mist. The exhaust gas enters the paint mist filter, which is filled with paint mist filtering material to remove over 90% of the paint dust. After exhaust gas purification, the activated carbon adsorption tower enters the bed through a pressure induced draft fan to adsorb organic (mainly actual reports) and activated carbon adsorbs exhaust gas (mainly actual reports).

Suitable for adsorption of organic compounds by activated carbon with high flow rate and low concentration (mainly based on actual reports) (mainly based on actual reports) and exhaust gas (mainly based on actual reports). Activated carbon adopts granular activated carbon with a specific surface area of up to 500-1500m2/g. The adsorption capacity of surface activated carbon is greater than that of surface area.

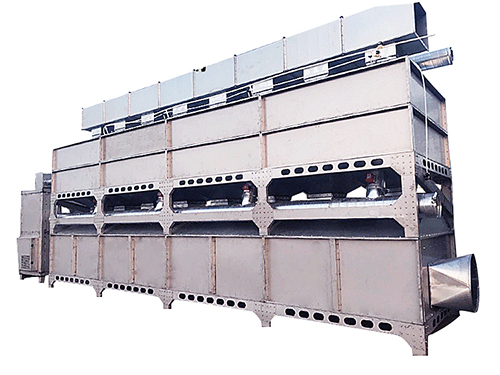

2. Spray booth exhaust gas treatment method 2: filtration catalytic combustion method

The organic (mainly based on actual reports) waste gas generated in the paint booth (mainly based on actual reports) is pumped into the paint dust pretreatment equipment outside the workshop through a collection hood, and then enters the adsorption, desorption, and catalytic combustion waste gas purification device.

The exhaust gas first passes through the filter layer of the dust filter to remove dust particles, and the purified gas enters the honeycomb activated carbon adsorption tower (activated carbon adsorption bed), where it fully contacts with the honeycomb activated carbon and uses activated carbon organic (mainly based on actual reports) (mainly based on actual reports) to strongly adsorb and purify the gas. Everywhere, there are specific substances that can meet the emission standards based on actual conditions.

The device has stable performance and can achieve the expected results. After a period of operation, the adsorption bed will reach adsorption saturation. The self balancing process will automatically cycle after 1 hour of starting. At this point, the desorption production system will be opened and activated carbon will be produced (without the need to replace activated carbon). The desorbed gas is burned by a catalytic combustion device, producing stable gases such as carbon dioxide, water, and some heat. The PLC will automatically control the entire adsorption and catalytic combustion process.

After saturation of activated carbon adsorption, hot air can be desorbed for production. After production, activated carbon can be reused. The concentration of organic (mainly based on actual reports) exhaust gas can be concentrated 10-15 times (mainly based on actual reports). The desorbed airflow is heated to around 300 ℃ by a catalytic bed combustion device and burned under the action of a catalyst. The purification efficiency of catalytic combustion process can reach over 90%. After combustion, carbon dioxide and carbon dioxide are produced, releasing a large amount of heat. This heat is heated by some heat exchangers in the catalytic combustion bed to produce activated carbon desorption gas from another portion of the outdoor air with higher concentration.

Catalytic combustion spray painting room exhaust gas treatment

Catalytic combustion spray painting room exhaust gas treatment