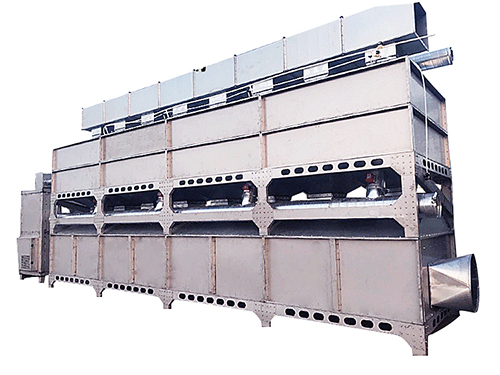

Catalytic combustion integrated machine is an excellent environmental protection equipment composed of catalytic combustion. The industrial scope of this equipment includes leather factories, chemical factories, petrochemical factories, rubber factories, paint rooms, and fine details. Our catalytic burner can be used in factories, plastic factories, foundries, refineries, printing and spraying factories, paint factories, slaughterhouses, waste treatment stations, and other industries.

Working principle of catalytic combustion integrated machine:

Organic (mainly based on actual reports) waste gas treatment (mainly based on actual reports) refers to the adsorption, filtration, and purification of organic (mainly based on actual reports) waste gas generated in industrial production processes (mainly based on actual reports). Usually, organic (mainly based on actual reports) (mainly based on actual reports) waste gas treatment includes formaldehyde organic (mainly based on actual reports) (mainly based on actual reports) waste gas treatment, benzene toluene xylene and other benzene based organic (mainly based on actual reports) (mainly based on actual reports) waste gas treatment, acetone butanone, organic (mainly based on actual reports) (mainly based on actual reports) waste gas treatment, ethyl acetate waste gas treatment, oil mist organic (mainly based on actual reports) waste gas treatment, furfural (mainly based on actual reports) organic (mainly based on actual reports) (mainly based on actual reports) (mainly based on actual reports) waste gas treatment. Waste gas treatment, styrene, acrylic acid organic (based on actual reports), waste gas treatment Resin treatment (mainly based on actual reports), organic (mainly based on actual reports), waste gas treatment, additives (mainly based on actual reports), organic (mainly based on actual reports), waste gas treatment, paint spray treatment (mainly based on actual reports), organic (mainly based on actual reports), waste gas treatment (mainly based on actual reports), organic (mainly based on actual reports), waste gas treatment, etc.

Catalytic combustion equipment sets desorption time based on exhaust gas content and daily working hours. Detachment usually takes 7-15 days. The detachment time is 3-5 hours. The desorption time of catalytic combustion equipment mainly depends on the filling amount of activated carbon and the iodine value of activated carbon. High filling amount of activated carbon, high iodine value, and long desorption time interval for catalytic combustion equipment. If the iodine value of activated carbon used in catalytic combustion equipment is low and the amount of activated carbon filling in the equipment is small, the catalytic combustion equipment is prone to saturation.

Instructions for using catalytic combustion integrated machine:

This purification device is designed based on two basic principles: adsorption () and catalytic combustion (energy-saving), namely adsorption concentration catalytic combustion method. The device adopts dual gas path continuous operation, and two adsorption beds can be used alternately.

The exhaust gas containing organic (mainly actual reports) (mainly actual reports) passes through a fan and an activated carbon adsorption layer. The organic (mainly actual reports) (mainly actual reports) is reliably intercepted by the activated carbon report, and the clean gas is discharged; After being saturated with activated carbon for a period of time, organic compounds (mainly actual reports) have been concentrated in the activated carbon.

Characteristics of catalytic combustion integrated machine:

(1) Widely applicable: Catalytic combustion can treat almost all organic hydrocarbons (mainly reported in practice), exhaust gases (mainly reported in practice), and odorous gases. The adsorption catalytic combustion method has a good treatment effect on low concentration, multi-component, and non recyclable waste gases emitted from industries such as chemical engineering, coatings, and insulation materials.

(2) Low combustion temperature and energy saving: Compared with direct combustion, organic (mainly based on actual reports) exhaust gas catalytic combustion has significant characteristics of low combustion temperature and low energy consumption. In some cases, catalytic combustion does not require external heating after reaching the combustion temperature.

(3) The entire process has no wastewater, and the purification process has no secondary pollution such as NOX.

(4) Various organic pollutants (mainly based on actual reports) can be removed simultaneously, with advantages such as simple process flow, compact equipment, and good operation.

(5) The advantages of low operating costs and good heat recovery rate.