The principle of VOCs catalytic combustion equipment:

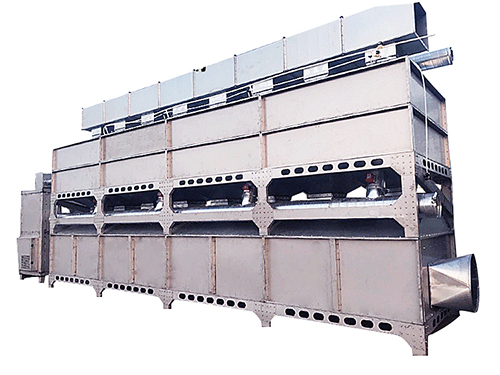

Thermal storage catalytic combustion is the organic (mainly actual reports) (mainly actual reports) (mainly actual reports) (mainly actual reports) (mainly actual reports) (mainly actual reports) generated under the action of a catalyst. The hydrocarbons in the exhaust gas are suitable for low-temperature oxidation into water and carbon dioxide to achieve the purpose of exhaust gas treatment. The catalytic combustion process is carried out in a catalytic combustion device. Organic (mainly based on actual reports) (mainly based on actual reports) waste gas (mainly based on actual reports) (mainly based on actual reports) should be preheated through a heat exchanger until the molecules of hydrocarbons and oxygen molecules in the mixed gas are adsorbed on the catalyst surface and turned on when entering the combustion chamber at 400 ℃. Due to surface adsorption reducing the activation energy of the reaction, hydrocarbons and oxygen molecules are suitable for oxidation at lower temperatures, producing carbon dioxide and water. The process of catalytic combustion equipment for volatile organic compounds (based on actual reports):

The adsorption desorption catalytic combustion system is typically used to treat low concentration high-volume organic (mainly based on actual reports) exhaust gases (mainly based on actual reports) (mainly based on actual reports) (mainly based on actual reports) (mainly based on actual reports) (mainly based on actual reports) (mainly based on actual reports) (mainly based on actual reports). Activated carbon is used to adsorb exhaust gases, and adsorption is stopped when saturation is reached. Then, hot air flow organic (mainly based on actual reports) (mainly based on actual reports) objects (mainly based on actual reports) (mainly based on actual reports) are separated from activated carbon to produce activated carbon. At this point, the separated organic (mainly based on actual reports) (mainly based on actual reports) objects (mainly based on actual reports) have been concentrated (with a concentration several tens of times higher than before) and sent to the thermal storage catalytic combustion chamber for catalytic combustion. The clean gas after combustion is discharged through the chimney.

Application of VOCs catalytic combustion equipment:

Thermal storage catalytic combustion equipment is suitable for the purification and odor elimination and treatment of volatile or leaked organic (mainly actual reports) waste gas (mainly actual reports) and volatile organic (mainly actual reports) waste gas in spraying, printing, electromechanical, household appliances, pharmaceuticals, footwear, plastics, and various chemical workshops. It is particularly suitable for low concentrations and not suitable for direct combustion, adsorption, and recovery of organic (mainly actual reports) waste gas (mainly actual reports). Therefore, for high air volume and low concentration exhaust gas treatment scenarios, satisfactory economic benefits can be achieved.