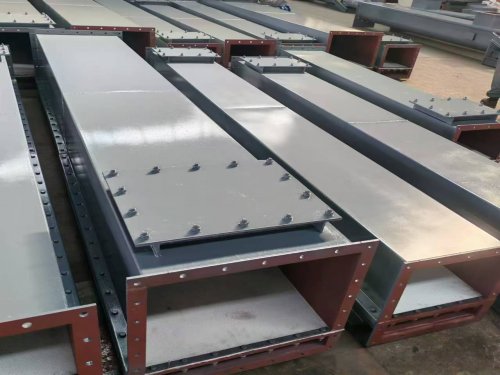

Dry ash powder conveying chute

Slant conveyor for dry ash powder

The dry ash powder conveying trough adopts a device that transports granular materials along the pipeline with airflow. There are three types: inhalation, pressure, and hybrid.

The working principle of the dry ash powder conveying chute is to use the kinetic energy of the airflow to suspend the granular materials and transport them along the pipeline with the airflow

1. Inhalation type. After the suction fan is started, the entire system presents a determined vacuum degree. Under the action of pressure difference, the air flow enters the suction nozzle and transports the material along the conveying pipe to the separator at the discharge point. After the material is separated from the air flow, it is discharged from the bottom of the separator, purified by a dust collector, and then discharged into the atmosphere through a muffler. The advantage is that the material supply is simple and can be absorbed from multiple places simultaneously. But the conveying distance is short and the productivity is low. High sealing requirements.

2. Pressure type. The blower presses air into the conveying pipe, and the material is supplied by the feeder. The mixture of air and material is pressed into the discharge area along the feeding pipe. The material is discharged through a separator, and the air is purified and discharged into the atmosphere through a dust collector. Unlike inhalation type, materials can be transported to multiple locations simultaneously, with long transportation distances and good productivity, but the structure is complex.

3. Mixed. The combination of the above two forms.

Reminder: This device should not use materials with large particle size, high moisture content, or poor fluidization!

Slant conveyor for dry ash powder

Dry ash powder conveying chute