Air conveying trough is a widely used equipment for transporting flowable powder materials, especially in industries such as cement and fly ash. The following is a detailed analysis of the air conveying trough:

Definition and working principle

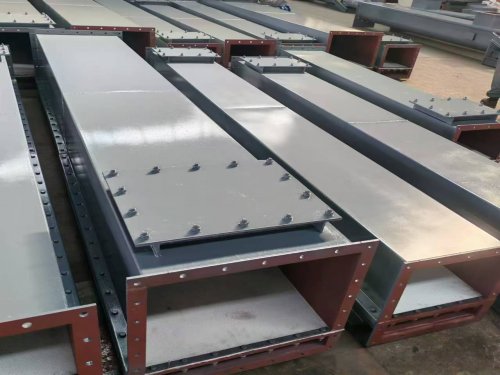

Definition: An air conveying trough is a device that uses airflow to transport granular materials along a pipeline, and belongs to a type of pneumatic conveying equipment. It maintains the flow of materials in the inclined chute through the airflow generated by high-pressure centrifugal fans or other air source equipment, thereby achieving continuous transportation of materials.

Working principle: The working principle of the air conveying chute is mainly based on the kinetic energy of the airflow, which suspends the granular materials and transports them along the pipeline with the airflow. Specifically, when a gas with a determined pressure is blown into the chamber of the inclined groove, the material flows through the breathable layer and flows inside the groove like a fluid under the action of gravity, thereby achieving transportation.

Features and advantages

No transmission part: The main body of the air conveying chute has no transmission part, with a simple structure and easy maintenance.

Good sealing performance: using a breathable layer for easy sealing management and reducing the risk of dust leakage.

Low power consumption: Due to the absence of transmission components and good airflow efficiency, the device has low power consumption.

High conveying power: capable of conveying a large amount of powdered materials, meeting the needs of industrial production.

Easy to change the conveying direction: By adjusting the layout of the inclined groove, the conveying direction of the material can be easily changed.

Multiple feeding and unloading: Air conveying chutes can achieve multiple feeding and unloading, improving production flexibility.

Thirdly, specifications, models, and performance parameters

There are various specifications and models to choose from for air conveying chutes. Different types of inclined slots vary in terms of slot width, conveying capacity, air pressure, and air volume. Taking a certain model as an example, its tank width can reach 500mm, and the conveying capacity (taking cement as an example) is 8 at an inclination angle. At ° C, it can reach 220T/H, with a wind pressure of 2-3KPa and an air volume of 1.5-2m ³/㎡. min.

Fourth, influencing factors

The conveying performance of an air conveying trough is influenced by various factors such as the permeability of the permeable layer, installation inclination angle, trough width, conveying air consumption, material moisture content, initial velocity, and conveying distance. Therefore, when designing and using air ducts, it is necessary to comprehensively consider these factors to confirm the conveying effect.

Fifth, the application industry

Air conveying troughs are widely used in the conveying industry of easily flowing powder materials such as cement and fly ash. In the cement industry, it is commonly used to transport materials such as cement and raw material powder, which improves production efficiency and the automation level of material transportation.

VI. Summary

Air conveying trough, as an energy-saving and environmentally friendly pneumatic conveying equipment, plays an important role in industrial production. Its reliable working principle and excellent performance characteristics make it have broad application prospects in the powder material conveying industry. With the continuous advancement of technology and optimization of processes, the performance of air conveying tanks will be further improved, bringing more convenience and benefits to industrial production.