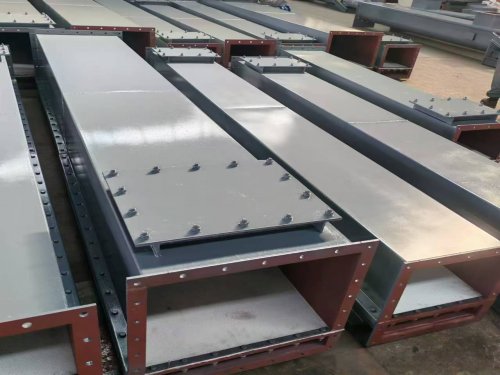

Every product we produce must undergo strict debugging and inspection. The specifications of the air conveying chute products are as follows:

Good sales, working principle

The air conveying trough is made of several thin steel plates and connected to accessories with bolts. There is a breathable layer sandwiched between the upper and lower troughs, and it is installed at a determined oblique angle from the feeding end to the discharging end. When a gas with a certain pressure is blown into the gas chamber, the material flows through the breathable layer and flows like a fluid in the gas tank under the action of gravity. Usually, a ventilation fan is used as the air source, and excess air in the material room is sucked away by the vacuum cleaner through the exhaust port.

Excellent, structural composition

It mainly includes tank components such as good sales volume, intermediate groove, curved groove, three-way groove, as well as accessories such as shut-off valve, control valve, gas supply pipeline, gas supply device, and structures such as breathable layer, wind deflector, dust removal port, etc.

3、 Characteristics

1. Advantages: No rotating parts, easy to maintain, less wear and tear; Good sealing performance, no noise, and good operational performance; Low power consumption, easy to change the conveying direction, multiple feeding and unloading.

Disadvantages: High requirements for the conveyed material, high humidity, easy formation of cohesive blocks, not suitable for using sticky materials; Material transportation requires a certain height difference and cannot be arranged horizontally.

Fourth, technical performance

Material conveying: Suitable for conveying dry powder materials with a moisture content of ≤ 1% and a temperature of ≤ 150 ℃, such as cement and raw material powder.

Conveying capacity: It is related to the width and inclination angle of the tank. For example, the width of the XZ200 tank is 200mm. When the inclination angle is 4 degrees, the cement conveying capacity is 22t/h and the raw material is 16t/h; Due to the increase in the width and inclination angle of the tank, the conveying capacity is also correspondingly improved.

Wind pressure and air volume: generally require 4-5.5. Wind pressure. KPa, The air volume is 1.5-2m ³/m ². min.

Fifth, the application industry

Widely used for conveying flowable powder materials such as cement, fly ash, gypsum powder, soda ash, etc., commonly used for conveying cement and raw material powder, and can also be used for conveying dry powder materials in industries such as chemical, metallurgical, and power.

After receiving our air conveyor chute products, our customer service is available 24 hours a day to provide consultation services and solve after-sales related problems for you. We look forward to working with you.