An air conveying chute is a device that uses compressed air to fluidized powdered materials and utilizes gravity to make them flow along an inclined chute. The device mainly consists of upper and lower tanks, breathable layers, and fans, and is suitable for horizontal transportation of dry powder materials such as cement and fly ash.

Structure and Working Principle

Core structure.

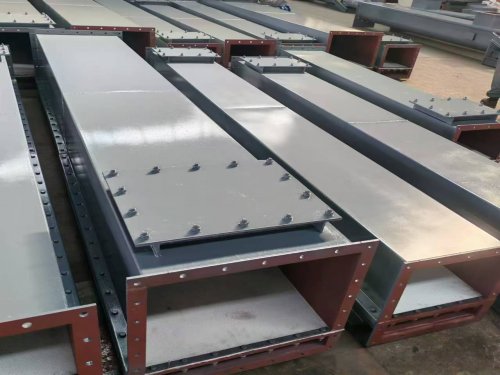

Composed of upper and lower groove bodies (made of thin steel plates) and breathable layers, arranged as a whole at a determined slope.

The breathable layer separates the material chamber (upper layer) and the air chamber (lower layer) of the tank, and the fan sends compressed air into the air chamber to penetrate the breathable layer and make the material fluidized.

Workflow.

The fluidized material slides along the inclined groove under the action of gravity, similar to fluid motion.

The excess air is processed by the dust removal system through the exhaust port.

Key features

Applicable materials: Only suitable for dry and easily fluidized powder materials (such as cement and fly ash), not suitable for materials with large particle size or high moisture content.

Advantages: No transmission components, low energy consumption, large conveying capacity, and flexible adjustment of conveying direction.

Limitations: The conveying distance is relatively short (generally ≤ 100 meters), and there is a high requirement for sealing.

Typical application scenarios

Transportation of cement clinker and raw materials in cement plants.

Sealed transportation of fly ash in the power and building materials industries.