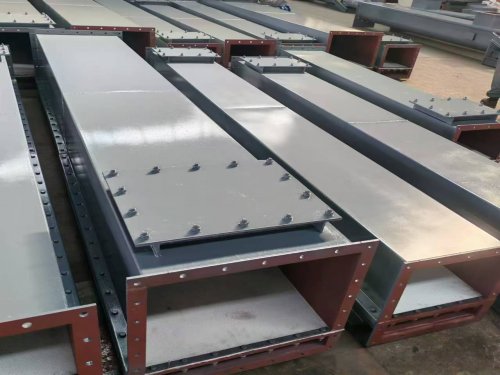

Use and maintenance of air conveying chute B315:

1. When starting, turn on the fan first before adding material. When shutting down, stop adding material first. Wait until the material is being fed (or close to being fed) before stopping the fan. Stop when the split fan is not in use;

2. The conveying tank should be sealed. If there is any air or powder leakage, it should be repaired;

3. Replace the polyester breathable layer:

a、 Cutting, cut the breathable layer according to the required size, heat the incision with an electric iron (or heating steel bar) to prevent specific dispersion of clinical effects;

b、 When piercing, heat with an iron rod slightly smaller than the diameter of the installation bolt, and the piercing needs to be done around the breathable layer. When punching, be careful not to let open flames burn out the breathable layer. If drilling with a drilling rig, iron it with a hot iron rod after drilling to prevent the dispersion of specific clinical effects;

c、 Lay the breathable layer on the punching box, thread it through the bolts, press it tightly with iron bars, and tighten the screw hairs;

d、 The pressure strip (or flange) should be deburred, and the welding area should be ground flat;

e、 To protect the air chute seal, polymer sealant (or 10mm thick felt pad) can be applied underneath the breathable layer.