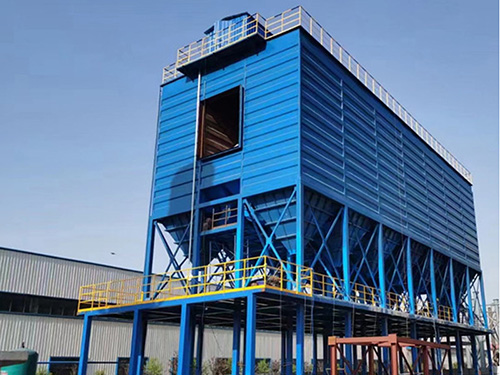

Under the principles of excellent technology, good operation, and economic rationality, a 10 ton coal-fired boiler dust collector should be designed to greatly reduce one-time investment, save energy and reduce consumption, facilitate system maintenance, extend the overall equipment life, and improve work efficiency by ten times. It plays a very important role in the economic development of enterprises.

Advantages of dust cleaning

The dust collector of a 10 ton coal-fired boiler adopts pulse dust removal technology, which has strong dust removal ability, good dust removal rate, and will not bring industrial pollutants such as dust and dirt after operation. Therefore, the workshop can be cleaned in the factory workshop, which plays an important role in environmental protection and can be loved by people.

Flame retardant design

Based on the characteristics of the working conditions of coal-fired boilers, a 10 ton coal-fired boiler dust collector was designed to achieve uniform airflow distribution in the dust removal equipment, reduce the temperature of dust gas, pre dust removal, and prevent sparks. Bag material is suitable for high temperature and high corrosion conditions of coal-fired boiler flue gas. Good performance has improved the service life of dust removal equipment.

fault inspection

When operating the dust collector of a 10 ton coal-fired boiler, it is necessary to regularly observe the emission concentration and check whether the filter bag is damaged. If damaged filter bags are found, they should be replaced in a timely manner. Regularly check the wear and tear of the movable parts of the dust cleaning mechanism, as well as the oil blockage of the compressed air nozzle and pulse nozzle mechanisms.