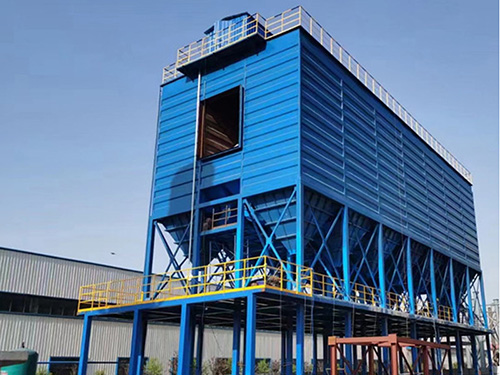

The main performance and characteristics of boiler bag filter:

1. Dust removal: The dust removal efficiency is good, and the emission concentration meets the requirements of the new environmental emission standards.

2. Low maintenance cost: Due to the improved performance of the equipment through structural design, use, and key components, the dust collector operates stably for a long time, and the maintenance cost is only about 70% of that of a general dust collector.

3. Long service life of filter bag: Pulse ash removal, filter bag and accessories extend the service life of filter bag. The structure of a boiler dust collector mainly includes a dust removal box, a dust removal box, an ash hopper, an inlet flow equalization device, a filtration unit, a soot blowing system, a dust removal system, brackets, ladders, guardrails, a boiler dust collector lighting system, a boiler dust collector over temperature display, a fault alarm system, a boiler dust collector PLC microcomputer control system, etc. It consists of upper, middle, and lower boxes, an ash discharge device, and a soot blowing system

The box on the boiler bag filter includes a lifting top cover and an air outlet. There are flower boards and filter bag components inside the box. The lower box has an ash hopper, air inlet, and maintenance door. The dust removal device of the boiler dust collector is a rotary discharge valve. The soot blowing system consists of a pulse controller, solenoid valve, blowing pipe, and Anran airbag.

The boiler bag filter is composed of an upper box, a middle box, an ash hopper, a guide pipe, a bracket, a filter bag assembly, a spraying device, an ash discharge valve, etc.

The dust collectors are arranged in double rows, with 3 warehouses in each row to shorten the length of the dust collectors and facilitate layout. Each warehouse is equipped with 1 ash hopper.

The specification of the filter bag is φ 160 × 6000 millimeters, with 792 dust collectors per unit and 12 filters per row, for a total of 66 rows. The upper end of the filter bag is equipped with a spring ring, which has good sealing performance and is easy to replace. Each filter bag has a carbon steel bag cage.

Electromagnetic pulse valve specification 3 ", 66 sets per dust collector, 11 sets per warehouse.

Use a programmable logic controller (PLC) controller with 12 offline valves.

The operation of the boiler bag filter is also equipped with a set of filter bag leak detection device and emergency water spray system.

The dust gas enters the ash hopper of each unit through the guide pipe. Under the guidance of the ash hopper diversion system, large particle dust directly falls into the ash hopper, while the remaining dust enters the middle box filtration zone with the airflow. The filtered clean gas is discharged through the filter bag, upper box, offline valve, and exhaust pipe. As the filtration progresses, when the surface area of the filter bag reaches a certain quantity, the dust removal control device should close the offline valve according to the set program, open the electromagnetic pulse valve, shake the dust on the filter bag, and discharge the dust that falls into the ash hopper through the dust removal valve.

Each warehouse takes turns spraying filter bags, about 5 minutes per warehouse, and 6 warehouses take turns spraying filter bags for about half an hour. Good sales, then spray, and so on.

The dust collector is equipped with a bypass flue. When starting the boiler, open the bypass flue to prevent ignition and poor oil combustion. The oil stuck to the filter bag, and the filter bag was burned out by an open flame. When the exhaust temperature of the boiler accident exceeds the allowable temperature of the filter bag, open the bypass.

The emergency blowing system of the dust collector uses industrial water to lower the flue gas to the allowable temperature of the filter bag. Each flue has two sets of nozzles, with good sales having two nozzles and four nozzles. When the flue gas temperature exceeds the design value, open the nozzle of the good sales group. If the temperature of the flue gas cannot decrease, open the group nozzle. If it still cannot decrease, an alarm signal will be issued to open the bypass system or stop furnace processing.

The boiler bag filter has five systems

1. Body: composed of upper box, middle box, ash hopper components, maintenance door, bracket, etc

The body design adopts unfavorable load combinations for strength design; Q23 board production.

2. Dust removal and filtration system: mainly composed of filter bags, bag cages, flower board components, ash hopper inlet manual control valve, and inlet distribution system.

3. Ash removal system: mainly composed of gas storage bag (including oil-water separator, pressure regulating device), electromagnetic pulse valve, nozzle assembly and offline valve, air gun and star shaped ash removal valve.

4. Protection and control, detection system: mainly composed of bypass system, differential pressure device, level gauge, thermometer, pressure detection device, pulse controller, filter bag detection device, etc.

5. Electrical control system: mainly composed of PLC main control cabinet (including installation position, pulse controller, filter bag leakage detection device, dust collector control components, and ash conveying control system).