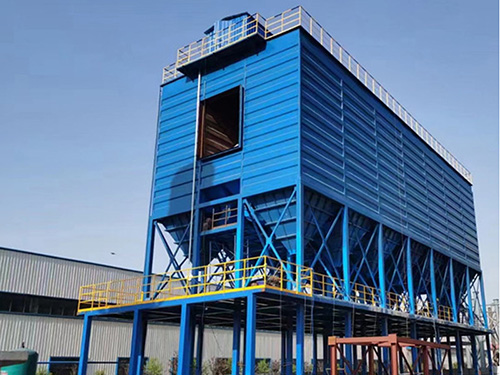

Boiler denitration dust collector is a dust removal equipment on coal-fired boilers. To prevent dust containing sparks from directly entering the dust collector and damaging the dust filter bag, and to improve the dust removal effect, a spark trap is installed in front of the dust collector inlet to crush and extinguish small sparks in the dust before entering the dust collector for filtration. The small boiler desulfurization, denitrification and dust collector adopts cooling measures to achieve a temperature below 120 ℃, saving the cost of using high-temperature cloth bags. The small boiler desulfurization and denitrification dust collector adopts a powder spraying device and a bypass device to prevent the dust filter bag from being stuck by smoke and dust, reduce the temperature entering the bag filter, and extend the service life of the bag. The inlet pipe of the desulfurization, denitrification, and dust removal system of the small boiler, the insulation of the dust removal box, and the insulation of the outer wall plate of the dust removal hopper after heating by the electric heating plate.

Characteristics of boiler denitrification and dust collector:

1. Dust collector has low dust removal, low emission concentration, low air leakage rate, low energy consumption, low steel consumption, small footprint, stable operation, and good economic benefits.

2. The filter cartridge is installed with a skeleton, which has good sealing performance and is firm.

3. The layout of the inlet and outlet air ducts is compact, with low airflow resistance.

4. The box adopts an airtight design with good sealing performance. The inspection door is made of excellent sealing materials, and the air leakage rate is very low.

Boiler desulfurization, denitrification, and dust removal devices are widely used in the desulfurization and dust removal industry of coal-fired boilers. They can adopt wet dust removal, wet desulfurization, and integrated dust removal, desulfurization, and dust removal. They are not only suitable for dust removal and desulfurization of coal-fired circulating fluidized bed boilers in power plants, but also for wet desulfurization and dust removal of coal-fired chain boilers, flue gas purification, sulfur dioxide, exhaust gas purification, dehydrogenation, kiln exhaust gas acid exhaust gas purification equipment, pellet and sintering machine exhaust gas desulfurization. working principle

(1) Pre separation: The dust gas emitted by the boiler enters the inlet pipe of the dust collector through the flue, and uniformly enters the bag room above the dust collector under the negative pressure generated by the induced draft fan of the dust removal system. Due to the obstruction of the deflector and its own gravity, the coarse particles of dust in the flue gas directly fall into the ash hopper, completing the pre separation of dust.

(2) Filtering: Dust containing gas enters the filter bag through the flower plate holes, and the dust is intercepted on the inner surface of the filter bag. The dusty gas is filtered and purified through a filter bag, and the purified gas enters the filter bag chamber. Then, it is discharged into the atmosphere from the exhaust fan through the exhaust channel and exhaust pipe of the lifting switching valve. The dust collector is an internal filter dust collector with top air outlet and negative pressure operation. The cleaning methods can be divided into two types: fixed time and resistance. Regularly clean the dust according to the time program, and each room automatically takes turns cleaning according to adjustable time parameters. The dust collector cleaning cycle is 0-6 levels, which can be adjusted within 2.5 hours. The cleaning time for each room is 10 seconds to select 6 levels for 3 minutes. Regular dust removal control is the process of sampling the pressure difference between the inlet and outlet of the dust collector, and converting it into an electrical signal through a pressure difference transmitter for dust removal. The workflow is as follows: In addition to the above two control methods, in addition to the solenoid valve cylinder lifting switch valve, the inlet and outlet pressure difference transmitter is also equipped with a manual control mechanism, which can manually perform normal dust removal control. For the convenience of operation and management, it is recommended to adopt the method of regular dust cleaning.

The working principle of the boiler desulfurization, denitrification, and dust collector is to reduce the generated NOx to N2, thereby removing NOx from the flue gas. According to the treatment process, it can be divided into wet denitrification and dry denitrification. Mainly including: acid absorption method, alkali absorption method, selective catalytic reduction method, non selective catalytic reduction method, adsorption method, ion activation method, etc. Some people also use microorganisms to treat NOX emissions. The desulfurization technology can be divided into wet, dry, and semi dry methods, depending on the dry and wet state of the absorbent and desulfurization products during the desulfurization process. Wet flue gas desulfurization technology is the use of absorbent containing solutions or slurries to desulfurize and treat desulfurization products in a wet state. This method has the advantages of desulfurization reaction, simple equipment, and desulfurization, but generally has problems such as severe corrosion, high operation and maintenance costs, and easy secondary pollution. The characteristic of wet desulfurization is that the desulfurization system is located at the end of the flue and after the dust collector. The reaction temperature during the desulfurization process is lower than the dew point, so the desulfurized flue gas needs to be reheated before it can be discharged. Because it is a gas-liquid reaction and desulfurization reaction, if lime is used as a desulfurizer, the desulfurization rate can reach 90% when Ca///S=1, which is suitable for flue gas desulfurization in large coal-fired power plants.