Biomass boiler dust collector is a dust removal equipment for biomass boilers. Biomass boiler is a type of boiler. A boiler that uses biomass as fuel is called a biomass boiler. Biomass boilers are divided into straw pressing biomass particles, splitting, sawdust, furniture factory waste, etc.

The biomass boiler adopts a combustion equipment suitable for biomass fuel combustion - reciprocating grate. In terms of structural design, the boiler space is larger than the traditional boiler furnace, and the arrangement of secondary air is very reasonable, which is conducive to the full combustion of a large amount of volatile components that precipitate instantly during biomass fuel combustion. The efficiency of biomass boilers is generally above 80%, with large boiler models, sufficient combustion, and good boiler efficiency. 88.3% higher than coal-fired boilers, with an average efficiency of 15%. Although biomass boilers have good efficiency, they still produce dust that pollutes the environment. Therefore, corresponding dust collectors are needed to solve the problem. Biomass boiler dust collectors have emerged.

There are significant differences between biomass boilers and traditional coal-fired boilers. There are two exhaust methods for biomass boilers. One is direct emission. Due to the relatively light weight of biomass fuel, the boiler flue gas will not be completely burned under the action of the induced draft fan, and the biomass particles will not be sucked into the bag filter, causing it to catch fire. After multiple experiments, based on the condition of the biomass boiler bag, the equipment uses a biomass boiler flame arrester. The flame arrester adopts the principle of collision and interception, which can intercept without interception. All burned biomass particles enter the biomass boiler bag filter. Another type is a three pass boiler that requires secondary combustion, and the emitted flue gas will not contain unburned biomass particles. The flue gas can directly enter the bag filter for treatment. The flue gas emitted by biomass boilers does not contain sulfur dioxide, so biomass boilers do not require the installation of desulfurization towers.

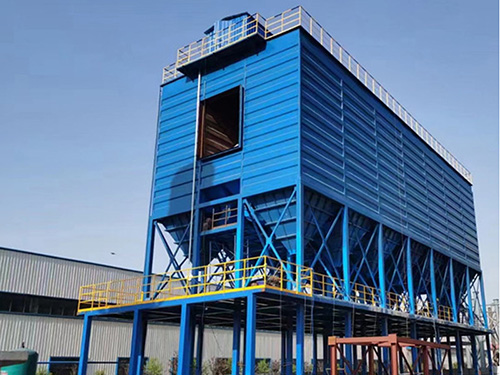

The boiler flue gas enters the biomass boiler dust collector through the inlet. Large particles of dust fall directly into the ash hopper. The gas containing particulate dust is left on the outer surface of the bag through the bag, and is purified by the induced draft fan before being discharged into the atmosphere. As the filtration process continues, the dust adhering to the outer surface of the filter bag increases, the operating resistance of the boiler bag dust collector increases, the conversion valve of the filtration unit closes, the filtration unit stops working, and reverse compressed air enters the filtration unit to blow off the dust on the outer surface of the bag. Then, the conversion valve plate is opened, the filtration unit resumes operation, and the dust is directed to the next filtration unit. Each filtering unit alternately carries out the entire dust cleaning process.

Protection measures for biomass boiler dust collector:

1. Bypass system: During boiler maintenance, flue gas can be directly discharged from the bypass pipeline, achieving non-stop boiler maintenance.

2. Pre spraying device: When the boiler enters the fuel, there will be a large amount of oil fume in the flue gas. Due to the adsorption of oil fumes on the surface of the bag, it can cause blockage and affect filtration. The pre spraying device sprays fuel into the boiler and lime powder into the flue gas pipeline to absorb the oil fumes in the flue gas and solve the problem of bag blockage.

3. Air cooling valve: The air cooling valve is equipped with an online temperature measurement system to monitor the flue gas temperature in real time. When the temperature of the flue gas exceeds the temperature that the bag can withstand, the air cooling valve will automatically open, and the dust collector will suck in some natural growth to protect the bag and cool the air.

4. Boiler dust collector insulation: After high-temperature combustion of fuel, the water in the fuel will turn into steam and flue gas and enter the bag filter. When the flue gas enters the bag filter, due to the large temperature difference between the inside and outside, it will naturally cool, causing the water vapor in the flue gas to form condensed water and adsorb on the surface of the bag. After filtration, water and dust will form mud on the surface of the bag, making it unable to filter. After the dust collector is insulated, the flue gas will not cool down after entering the dust collector, and water vapor will not form condensed water, avoiding bag sticking.