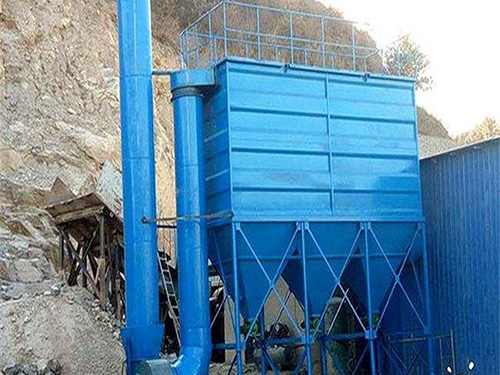

Electric furnace motor dust collector

The characteristics of flue gas from electric furnace dust collectors are: firstly, the flue gas content and heat content are high, and the heat carried away by the flue gas is about 33% of the input energy; Secondly, the smoke and dust are fine, with about 90% less than 1um, and the smoke and dust capacity is light, only 200kg per cubic meter. Thirdly, the main component of smoke and dust is SiO2.

The electric furnace dust collector (electric arc furnace dust collector) system is designed for the future industrial silicon production of electric furnace flue gas. The flue gas is discharged from the semi enclosed electric furnace and enters the cyclone dust collector along the flue. Separate coarse particles from sparks and settle them in the ash hopper until discharged by the unloader. When the outlet of the cyclone dust collector is discharged, the dust and dust gas enter the heat exchanger, and the air cooling reduces the flue gas temperature. Then, other dust particles rise with the airflow and enter each bag chamber of the bag filter. After the filter bag is filtered, dust clogs outside the filter bag. The purified gas enters the box through the filter bag, and then enters the centrifugal main fan through the bag opening and the outlet of the upper box (clean air chamber), and is discharged into the chimney to the atmosphere. The dust in the ash hopper is regularly or continuously discharged by the ash unloading system.

The flue gas treatment of electric furnace dust collectors has always been a major problem for domestic ferrosilicon enterprises. For a long time, environmental protection technicians in China have done a lot of work, trying to adopt various dust removal technologies, but the dust removal effect is not very good. In August 2000, after detailed on-site investigation, our company's main technical personnel designed the LCDM series low-voltage long bag pulse bag dust collector, which has the characteristics of semi enclosed calcium carbide furnace dust removal waste gas. It was successfully built and put into operation on the 800KVA semi enclosed calcium carbide furnace of Shaanxi Chemical Plant, achieving good results. The dust collector has been running continuously and is very stable in use. The dust emissions are always below the emission standards, and the average service life of the filter bag of the electric furnace dust collector exceeds one year.

Electric furnace motor dust collector