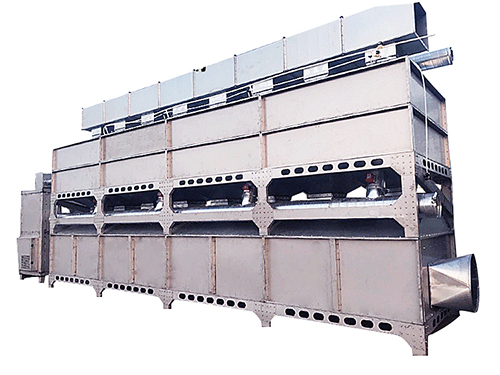

Activated carbon filter catalyst combustion purification

The catalytic combustion purification of activated carbon filtration device mainly utilizes the adsorption effect of porous solid adsorbent activated carbon. In addition to pollutants and odors in industrial waste gas, it is also widely used in the final treatment of industrial waste gas purification, with good purification effect. After entering the absorption tower through the pipeline, the gas undergoes a diffusion process between two different phase interfaces. After diffusion, the gas is sucked out and discharged by the fan.

Activated carbon is an economical and practical exhaust gas purification and treatment device. It has the advantages of simple structure, convenient maintenance and management, low energy consumption, stable operation, low failure rate, adsorption, purification, and pretreatment. At the same time, based on relevant parameters such as exhaust gas emission temperature, oil mist, dust, etc., pre-treatment devices or functional parts such as coolers and filters are built or added to the exhaust gas equipment to protect the adsorption part, and the adsorption box operates in a state. This device can adsorb and purify exhaust gases from solvents such as benzene, ketones, alcohols, esters, and gasoline, and is suitable for working environments with low concentration, high air volume, or intermittent exhaust emissions. Can purify the environment, pollution, worker health, and control emission standards.

Activated carbon purifier is a dry exhaust gas treatment device consisting of a box and an adsorption device filled inside the box. Different fillers can treat different types of exhaust gases. The exhaust gas is filtered to remove solid particles and enters the adsorption tank from top to bottom. The objects are absorbed and concentrated by activated carbon, and the purified air is discharged into the atmosphere from the lower part of the tank through a fan. When the activated carbon adsorbate reaches saturation, stop inhaling the exhaust gas. Steam is sent upwards through the activated carbon bed for blowing and desorption, removing objects from the activated carbon and desorbing them. The recovery of activated carbon in the tank is mainly clinical and regenerative.

Catalyst combustion purification parameters: Activated carbon filtration device:

1. 5000 air volume

2. Types of waste gas treatment: adsorption and purification of waste gas from solvents such as benzene, alcohols, ketones, esters, gasoline, etc

3. Main equipment materials: PP polypropylene

4. Purification rate: over 90%

5. Starting temperature: 100 ℃

6. Size and dimensions can be customized according to customer needs

7. Application: Purification of exhaust gases and odors generated by industries such as chemical, light industry, painting, electronics, electromechanical, printing, household appliances, footwear, batteries (batteries), optional plastics, films, rubber, coatings, pharmaceuticals, furniture, ships, automobiles, petroleum, etc.

Activated carbon filtration device catalyst combustion purification