Rubber factory exhaust gas deodorization equipment

Rubber factory exhaust gas deodorization equipment

Rubber factory exhaust gas deodorization equipment is suitable for exhaust gas purification in industries such as paint, rubber, paint, plastic products, printing ink, petrochemicals, wires, cables, paint wires, machinery, motors, chemicals, instruments, automobiles, bicycles, motorcycles, engines, magnetic tapes, plastics, household appliances, etc.

The deodorization equipment for exhaust gas in rubber factories is easy to operate, easy to maintain, has low operating costs, and has a high VOCs removal rate. Low fuel consumption, low equipment cost, and decomposition temperature of 220-380 ℃. CO is decomposed using low-temperature catalyst method, staying in the catalytic chamber at 1-1.5/s. The cross-sectional air velocity ratio of the exhaust gas placed on the catalytic carrier is 15000h to convert CH compounds into CO2 and H2O, in order to control pollution. Suitable for processing various exhaust gases with concentrations ranging from 2000 to 10000 mg/m3. According to the concentration ratio of VOCs, the decomposition area is designed, and the oxidation catalyst flows through the catalytic chamber through a positive pressure exchanger. The purified high-temperature flue gas is preheated to combustion temperature through heat exchange, maintaining the system operating without heating power. If the flue gas temperature is high after preheating the exhaust gas, it can also be used to heat fresh air or water, generate water vapor, achieve thermal energy reuse, and reduce exhaust gas treatment and production energy consumption.

Rubber factory exhaust gas deodorization equipment is a new catalytic technology with the advantages of purification and low-temperature catalytic reaction. Place the catalyst in the middle of the catalytic chamber to achieve the desired purification state. What are the thermal characteristics during exhaust gas treatment?

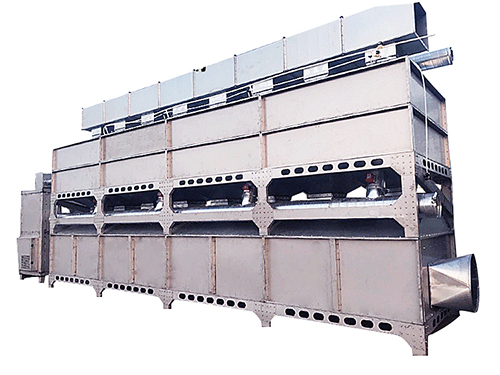

The deodorization equipment for exhaust gas in rubber factories mainly includes heat exchange chambers, catalytic chambers, heat exchange chambers, fans, combustion systems, etc. By absorbing the oxidation heat in the exhaust gas, new exhaust gas can be preheated, reducing the heat emissions after exhaust gas treatment, saving the oxidation heat loss in the exhaust gas, and maintaining the high thermal efficiency of the exhaust gas during the high-temperature oxidation process.

Rubber factory exhaust gas deodorization equipment

Rubber factory exhaust gas deodorization equipment