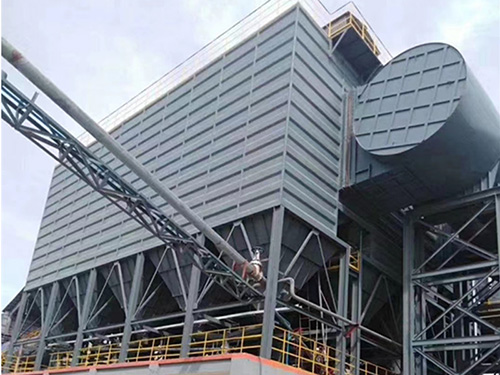

PPC gas box bag filter

The working principle of PPC air box pulse dust collector:

The dusty gas enters the inclined partition through the inlet and outlet of the dust collector (A series enters from the ash hopper), and the airflow velocity slows down. Due to inertia, coarse dust in the gas falls into the ash hopper, while fine dust folds into the filtering chamber with the airflow. Dust adheres to the appearance of the dust removal bag. The purified gas enters the upper clean room through the filter bag, is collected through the air outlet, and is sucked out by the main fan of the dust removal system and discharged into the atmosphere.

As the filtering conditions continue, the amount of dust adhering to the surface of the filter bag gradually increases, and the resistance of the airflow passing through also gradually increases. When the resistance value (such as 1990Pa) is reached, the lifting valve of the bag dust collector head can be manually or automatically controlled by a fixed pressure or periodic dust removal pulse controller to cut off the airflow in the filter chamber. Then, the high-pressure compressed air released by the electromagnetic pulse valve and pulse blowing (stop air dust removal) can be opened to suddenly expand each filter bag, reduce the dust adhering to the surface of the bag, restore the pressure difference between the inside and outside of the bag to the starting state, and allow the dust to sink into the bucket. Then the program controller opens the lift valve at regular intervals to restore good indoor filtration, starts the indoor lift valve, closes the indoor filtration airflow, opens the indoor solenoid valve to release high-pressure compressed air, stops air pulse blowing, and removes dust from the indoor filter bag. Then, the program controller opens the lift valve at regular intervals to restore sales and filter the room. It then starts the partition lift valve, closes the partition filter airflow, opens the partition solenoid valve to release high-pressure compressed air, stops air pulse blowing, and filters the dust on the partition filter bag. Then the program controller opens the lift valve of the partition to restore the filtering of the partition. Afterwards, according to the predetermined electronic control program, the third and fourth compartments are divided The filter bag stops blowing dust until the cleaning of the next compartment is completed, the electronic control instrument is turned off, and the dust collector is fully restored to formal filtering and dust removal.

The application scope of PPC air box pulse dust collector:

PPC air box pulse dust collector; It can be widely used in crushing installation, warehouse roof, mature coolers, grinding machines and other collection systems in cement plants. PPC dust collectors come in 33 specifications, with 32 bags per room and 4 types of bags: 64, 96, and 128. The filter bag lengths are 2450mm and 3060mm, respectively, and the dust removal efficiency can reach over 90%. After purification by this series of dust collectors, the dust concentration in the gas is less than 100mg/m3 (standard). If used in cold regions, the ≤ - heating device should be set at 25 ℃ when calculating the outdoor heating temperature.

PPC gas box bag filter