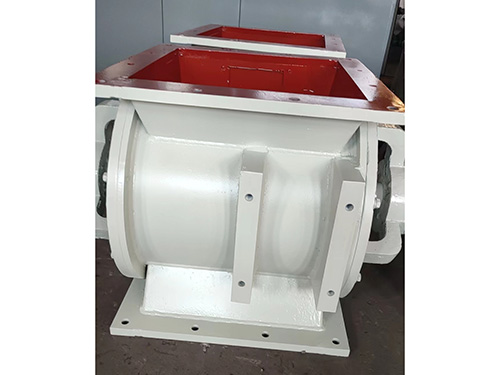

High temperature sealed unloader

Characteristics of High Temperature Sealed Unloader:

High temperature sealed unloader; Mainly made of stainless steel. The impeller has elasticity and good sealing performance, eliminating the phenomenon of impeller jamming. The bearing is located outside the valve body, and the material particles do not directly contact the reducer, which extends the service life of the star shaped unloader and facilitates maintenance. The stainless steel star shaped unloader has a stainless steel shell, which is corrosion-resistant (based on actual reports) and has good hardness (based on actual reports). It is not easy to adhere and is easy to transport medicinal herbs, food, and materials. The large 60 type electric star shaped unloader motor produced by our factory adopts a 4KW variable frequency motor, equipped with a No. 5 reducer, and can freely adjust the speed ratio.

Mechanical seal, also known as end face seal, is a dynamic seal for rotating shafts. Mechanical seal is a shaft sealing device that, under the action of fluid pressure and compensation mechanism elasticity (or magnetic force), maintains connection through one or several pairs of end faces perpendicular to the shaft and achieves auxiliary sealing.

Mechanical seals have excellent performance, minimal leakage, long service life, and low power consumption. Suitable for production processes involving automation, high temperature, low temperature, high pressure, vacuum, high speed, and various highly corrosive media, including harsh conditions such as solid particle media that require hunger sealing.

High temperature sealed unloader