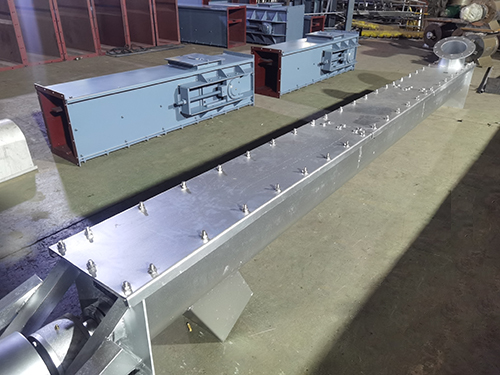

Stainless steel screw conveyor uses a rotating screw to move and transport materials along a fixed shell. The direction of rotation of the stainless steel screw conveyor shaft determines the direction of material transportation.

Stainless steel screw conveyors are widely used in industries such as food, seasoning, pesticides, veterinary drugs, building materials, chemicals, electricity, metallurgy, coal mines, and grain. They are suitable for industries such as food, seasoning food, pesticides, feed, coal mines, ash, slag, cement, grain, chemical, pharmaceutical, food, or environmental engineering wastewater and sludge treatment equipment. Stainless steel screw conveyors are not suitable for conveying materials that are prone to deterioration, high viscosity, and clumping.

Working principle of stainless steel screw conveyor:

Stainless steel screw conveyor; The rotating spiral blades during operation propel the transportation of materials, and the force that prevents the materials from rotating with the blades of the spiral hoist is the weight of the materials themselves and the frictional resistance of the spiral hoist shell to the materials. The rotating shaft of the spiral elevator is welded with spiral blades, and the surface types of the blades include solid surface type, strip surface type, blade surface type, etc. At the end of the material movement direction, the spiral shaft of the spiral elevator has a thrust bearing. When the spiral tube is long, an intermediate suspension bearing should be added. The general wear parts of a screw conveyor are suspension bearings, screw ends, and screw blades. In addition to natural factors such as temperature, environment, and materials, there are also structural and human factors. Next, let's analyze the reasons for the damage to the spiral blades of the screw conveyor.

Spiral conveyors are generally not easily blocked or have discharge ports that do not discharge, and can operate at low speeds to reduce energy consumption. The screw conveyor has a long conveying distance and can be installed in multiple stages in series to transport materials within a certain distance. But sometimes, when household waste and organic materials (mainly based on actual reports) are transported to plants (mainly based on actual reports), the spiral blades can also be damaged.

The thickness of spiral blades is more practical and suitable for conveying materials. The wear of spiral blades mainly occurs at the edges of the blades. The farther away from the axis of rotation, the greater the force, and the more empty cracks will form.