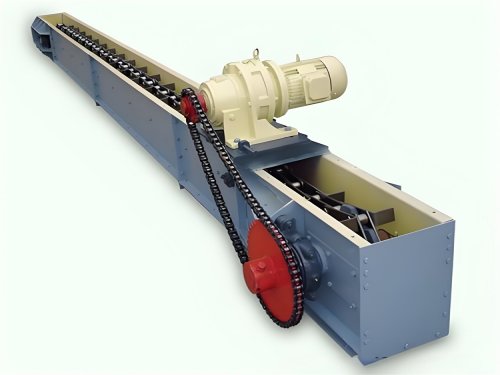

The FU scraper chain conveyor is mainly composed of a closed cross-section shell (groove), and the scraper chain is composed of a driving device, a tensioning device, and a protective device. The device has a simple structure, small size, good sealing performance, and easy installation and maintenance; More feed and discharge, flexible process selection; When transporting flying, toxic, high-temperature, flammable and explosive materials, working conditions can reduce environmental pollution. The models include: general type, thermal type, high temperature type, performance type (mainly actual reports) (mainly actual reports), one-to-one soda ash (general type), one-to-one grain, one-to-one cement, one-to-one power plant, with a slot width of 160-1250mm.

The buried scraper conveyor has a reasonable overall structure and can be fed or unloaded at multiple points. Scraper chain scraper conveyor is a popular bulk material conveying system equipment in metallurgy, mining, and thermal power plants. It runs uniformly, smoothly, and with low noise under the transmission of reducer. The buried scraper conveyor includes MS, MC, MZ. There are three series of buried scraper conveyors to choose from. Bulk materials are a type of transportation equipment that is continuously transported within a closed rectangular or circular tube casing using a moving scraper chain.

The working principle of FU scraper chain conveyor:

Buried scraper conveyor is a transportation equipment used to move scraper chains within a closed enclosure, enabling bulk materials to be transported according to predetermined targets. It has the advantages of small size, good sealing, good rigidity, flexible process layout, easy installation and maintenance, multiple feeding and unloading. So, the working conditions of workers are obvious to prevent environmental pollution. The principle of buried scraper conveyor depends on the internal friction of the material and the lateral pressure of the shell feeding. During the process of conveying materials, the pressure in the direction of movement of the scraper chain and the pushing force of the lower material on the upper material during continuous feeding. The synthesis of this force is sufficient to overcome the external frictional resistance between the material and the shell, as well as the weight of the material itself. Materials can form a continuous material flow and move forward, whether it is horizontal conveying, inclined conveying, or vertical conveying.

The buried scraper conveyor is a type of conveyor with flexible traction components. Its conveying principle is different from that of a scraper conveyor. Scraper conveyor is a type of buried scraper fixed on a chain, with intermittent material.