Good sales, structural composition

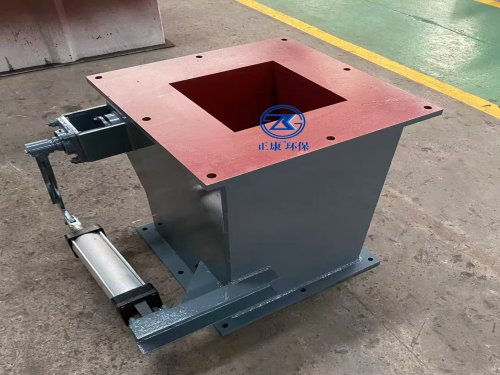

Valve body: Generally made of welded steel plates, providing different shapes of flow channels for materials, such as square, circular, etc., which can be selected according to actual installation requirements.

Flip board: installed in the middle of the valve body, usually circular or rectangular, connected to the valve body through a valve shaft, and can rotate around the shaft to control the flow of materials.

Valve shaft: used to connect the flap and valve body, allowing the flap to rotate flexibly. The valve shaft needs to have sufficient strength and performance to confirm that it will not deform or be damaged during long-term use.

Heavy hammer: installed on one side of the flipper, using its weight to control the switch of the flipper. By adjusting the weight and position of the heavy hammer, the opening pressure and closing speed of the valve can be changed.

Sealing element: Generally made of rubber or other materials, it is installed at the contact between the flap and the valve body to protect the valve from sealing in the closed state and prevent material leakage.

Secondly, the working principle

1. Automatic control principle: The heavy hammer flap valve uses the self weight of the material and the weight of the heavy hammer to achieve automatic opening and closing. When the material accumulates above the flipping plate and the pressure generated is greater than the weight of the heavy hammer, the flipping plate rotates around the valve axis to open, and the material can pass through; After the material falls, the weight of the heavy hammer automatically closes the flipper to prevent air from entering.

2. Working process of dual hammer flap valve: The dual hammer flap valve is divided into upper and lower layers. When working, the mechanical drive opens the upper valve, and the weight of the material decreases. The upper valve closes automatically under the action of the balance weight; Then the mechanical drive opens the lower valve, and the material continues to descend. The lower valve is closed by balancing the counterweight, completing one ash removal cycle. This design can prevent wild winds from blowing in and achieve a good wind locking effect.

Thirdly, performance characteristics

1. Automatic operation: relying on the gravity of the material itself and the balance of the heavy hammer, without the need for an external power source, it achieves automatic opening and closing, reducing energy consumption and equipment costs, while also reducing the risk of equipment shutdown caused by electrical failures or power system problems.

Simple structure: mainly composed of basic components such as valve body, flap, valve shaft, heavy hammer, seals, etc. The transmission mechanism and control system are not complex, easy to maintain, low maintenance cost, and stable operation in harsh working environments.

3. Good sealing performance: The use of specially designed sealing structures such as angled sealing surfaces, rubber or metal pads, and excellent sealing materials can prevent material leakage and air ingress, protecting the sealing performance and stability of the system.

4. Performance: Valve plates and bodies are usually made of wear-resistant materials such as stainless steel, wear-resistant (based on actual reports) (based on actual reports), cast iron, etc. They are not easily damaged under material erosion and friction, have a long service life, and are particularly suitable for handling materials with good hardness and high corrosiveness.

5. Wide applicability: It can be used for the transportation and unloading system of powder and granular materials in multiple industries such as metallurgy, chemical industry, power, building materials, mining, and grain. And it can adapt to different working temperatures, pressures, and material characteristics.

Fourth, the application industry

1. Dust removal system: In various environmentally friendly dust removal equipment such as bag filters and cyclone dust collectors, it serves as a discharge device for ash hoppers, regularly discharging collected dust to prevent external air from entering the dust collector and affecting the dust removal effect.

2. Material conveying system: used to control the flow and direction of materials in the conveying pipeline of powder or granular materials, achieving quantitative conveying and distribution of materials such as coal powder, cement, lime, and grain.

Pneumatic conveying system: used as a shut-off valve during the pneumatic conveying process to prevent material backflow and leakage, and to confirm the normal operation of the pneumatic conveying system.

Warehouse system: installed at the bottom of the warehouse or ash hopper, used for unloading and emptying materials, facilitating the storage and transportation of materials, and improving the efficiency of the warehouse system.