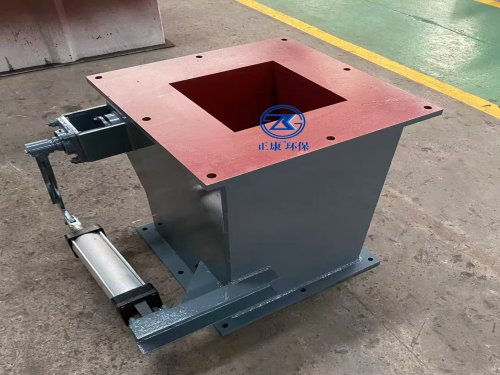

The working principle of the double door pneumatic flap valve is to drive the valve plate to automatically open and close under the action of material gravity through a pneumatic device. When the material falls onto the valve plate, the valve plate opens and unloads, causing the material to fall behind. The counterweight lever system automatically resets the valve plate to prevent wild winds from blowing in. Then, open two valve plates to allow the material to fall onto the conveying equipment below, completing the ash removal cycle.

The structural characteristics of the double door pneumatic flap valve include steel plate welding structure, smooth transmission, no impact, few replacement parts, and easy use. Excellent. It is divided into upper and lower layers. During operation, the upper valve is mechanically driven to open, the upper valve is automatically closed by the balance weight, the lower valve is mechanically driven to open, and the lower valve is closed by the balance weight.

The application scenarios include ash hopper unloading devices and various equipment such as mills, dryers, and silos as unloading devices for various dust removal equipment to prevent wild winds from blowing in. In addition, the double-layer air lock valve mainly utilizes the opening and closing of the upper and lower valves at different times, so that there is always a layer of valve plate in the middle of the equipment to close the partition and prevent air flow. Under positive pressure conveying, the pneumatic double-layer air lock valve can also serve as an auxiliary balancing and boosting valve, meeting the requirements of pneumatic conveying of powder materials