Explosion proof (based on actual reports) unloader

Explosion proof (based on actual reports) (based on actual reports) unloader

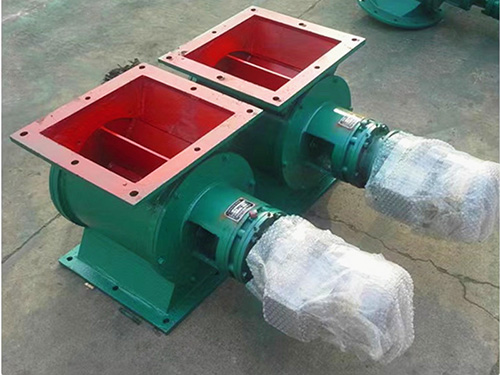

Explosion proof (based on actual reports) star shaped unloader; Mainly used in some flammable and explosive high-risk environments, the star shaped unloader produced is made of materials, and the rotor and impeller are made of aluminum that is not prone to spark discharge. The star shaped ash discharge valve produced by Youcheng Machinery uses pure aluminum rotors and aluminum impellers, which have requirements for the on-site environment. Explosion proof (based on actual reports) (based on actual reports) (based on actual reports) The unloader has a compact structure, beautiful and elegant design, smooth operation, and low noise. Especially the distance between the gearbox design and the body effectively solves the heat dissipation problem of the equipment. Explosion proof (based on actual reports) (based on actual reports) (based on actual reports) Unloader is the main equipment of dust removal equipment, suitable for powder materials, granular materials, powder materials and granular materials, widely used in environmental protection, metallurgy, chemical industry, grain, food and other industries. Explosion proof (based on actual reports) (based on actual reports) (based on actual reports) The unloader has a compact structure, beautiful appearance, easy use, smooth operation, and low noise. Due to the distance between the bearings and gearbox and the housing, the explosion-proof (based on actual reports) (based on actual reports) (based on actual reports) unloader has a significant impact on high temperatures. Explosion proof (based on actual reports) (based on actual reports) (based on actual reports) The unloader adopts the principle of planetary rotation, with input and output shafts on the same shaft, directly connected to the motor, compact structure, beautiful and novel appearance, small volume, and light weight.

1、 Explosion proof (based on actual reports) (based on actual reports) (mainly based on actual reports) Characteristics of unloading devices:

1. Explosion proof (based on actual reports) (based on actual reports) (based on actual reports) The unloader has a compact structure, beautiful appearance, and easy to use.

2. Smooth operation with low noise.

3. Due to the distance between the bearings and gearbox and the housing, the explosion-proof (based on actual reports) (based on actual reports) (based on actual reports) unloader has a significant impact on high temperature and lubrication.

4. Explosion proof (based on actual reports) (based on actual reports) (based on actual reports) Unloading machines can also be designed and manufactured according to user requirements.

5. Inject lubricating grease into the pin wheel cycloidal reducer at the factory, please check the oil filling regularly.

6. If there is a star shaped unloader grade, please specify it in advance when ordering.

Explosion proof (based on actual reports) (based on actual reports) (based on actual reports) Unloading machines are mainly used in high-risk environments that are flammable and explosive. All star shaped unloaders are made of materials, and the rotor and impeller are made of aluminum, which is not prone to spark discharge. The transmission motor is manufactured by domestic manufacturers, with models of 380V and 450V.

2、 Precautions for using a star shaped unloader:

1. Before using the star shaped unloader, check the quantity and type of lubricating oil in the reducer, replace it with new oil after one month of operation, and replace it once a year.

2. Connect the air source interface, check if the interface is blocked by foreign objects, and if the interface is clean;

3. Before using the star shaped unloader, please confirm that the rotation direction of the rotor is clockwise (extending from the reducer to the shaft end, consistent with the arrow on the sprocket cover);

4. Before using the star shaped unloader, open the sprocket cover to check the tension of the chain, and regularly check it during operation; At the same time, apply appropriate lubricating grease on the chain and sprocket;

5. During the whole use of the unloader, adjust the pressure reducing valve so that the sealing pressure is 0, 05 MPa higher than the material pressure in the valve body, which is suitable for oil-free, dry compressed air;

6. The gas source at the sealed area always exists throughout the entire use of the star shaped unloader, and can only be closed after confirming that the valve has stopped running;

3、 Common faults of star shaped unloader:

1. The star shaped unloader should be kept stable during transportation and installation, avoiding collisions and even shell fracture and deformation.

2. Before leaving the factory, the reducer has been injected with No. 0 lubricating grease, and lithium based lubricating grease has been injected into the ash discharge valve. Transmission and bearing components should be replenished or replaced within 6-10 months after being put into use. If the ambient temperature is high, humid, or there is too much dust in the air, the oil change time should be appropriately shortened.

3. During use, if the equipment leaks air or dust along the axial direction, it can be covered with a cover.

4. During operation, avoid equipment overload caused by large material particles and strong adhesion, or equipment damage caused by short circuits in the equipment casing or motor. It is recommended that users check and install overload protection devices in a timely manner.

5. This machine is suitable for continuous working systems and allows for forward and reverse operation.

6. The output shaft, input shaft and other components of the unloader should not be directly hammered to avoid damage.

Explosion proof (based on actual reports) (based on actual reports) unloader

Explosion proof (based on actual reports) unloader