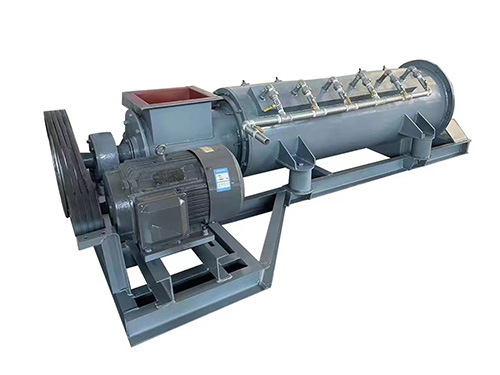

Single axis 60 type dust humidification mixer

Single axis 60 dust humidification mixer

The working principle and characteristics of a single axis 60 dust humidification mixer:

Dust humidifier; It consists of four parts: uniform supply, blade conveying, mixed impact humidification, vibration system, etc., and is equipped with a one-to-one electrical control and water supply system. The entire equipment is fixed on the base, and the cylinder is supported by four sets of elastic elements. Through vibration of the vibration device, the gap between the cylinder wall and the mixing shaft is maintained, and the running resistance of the entire machine is greatly reduced, all of which reject stuffiness and blockage, reduce downtime and cleaning time, and improve work efficiency. The water supply is controlled by a valve group. In order to stabilize the water supply and clean the water quality of the system, filters are installed in the pipeline. The various parts of the humidifier are interlocked and controlled by the main control cabinet to ensure constant humidity operation of the water supply. The stirring humidifier has the characteristics of large processing capacity, compact structure, excellent technology, good stability, and simple maintenance.

Advantages of a single axis 60 dust humidification mixer:

1. High output (can stir and humidify 200t per hour), uniform humidification, and good performance.

2. The atomizing nozzle and adjustable water supply system can protect the material from uniform humidification.

3. Added a vibration system to overcome the problem of sticky dust easily forming cylinder wall adhesion, improved the adaptability of the humidifier, and expanded the application range of the humidifier. The shell and base are connected elastically, so that vibration has no impact on the whole machine.

4. Iron based alloys or composite ceramics with long service life used for stirring rod performance (mainly based on actual reports).

5. The inner lining of the shell is made of iron-based performance (mainly based on actual reports) alloy, which has a long service life and avoids material self flow caused by excessive clearance after wear.

6. The layout of this machine is flexible, with two forms of chain transmission and direct connection. The transmission mechanism adopts a cycloidal reducer.

Used for single axis 60 dust humidification mixer:

It is generally suitable for spraying, humidifying, stirring, and transporting dry ash from various ash storage facilities to meet the requirements of environmentally friendly transportation. Widely used for humidification, mixing, and transportation of solid particulate materials in chemical, mining, power plants, steel mills, and other industries.

Single axis 60 dust humidification mixer

Single axis 60 type dust humidification mixer