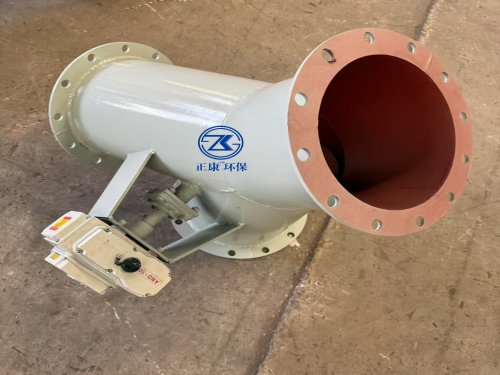

The working principle of the electric three-way distributor is to drive the rotating shaft mechanism of the three energy distributor through an electric push rod to control the flipping of the flipping plate and achieve the function of material reversal.

Electric push rod is an electric drive device that converts the rotational motion of an electric motor into the linear reciprocating motion of a push rod. Electric push rod is a universal auxiliary driving device in practical applications, widely used in industries such as power, machinery, metallurgy, transportation, mining, petroleum, chemical, lifting, transportation, construction, and grain and feed processing. Electric push rods have excellent performance, sensitive action, smooth operation, equal pushing and pulling force, and can adapt to various environments. The main structure of the electric push rod three-way distributor: The important components of the electric push rod include the drive motor, reduction gear, screw, nut, guide sleeve, push rod, slide seat, spring, main engine housing and turbine, micro control switch, etc. Working principle of electric push rod three-way distributor: In actual operation, the electric motor drives a pair of auxiliary screw nuts after being decelerated by the reducer. Transform the rotational motion of the motor into linear motion, and use the forward and reverse rotation of the motor to complete the push rod action. Complex movements such as rotation and shaking can be accomplished through various mechanisms such as levers, joysticks, or linkages. By changing the length of the lever arm, the stroke can be increased. Electric push rod three-way distributor stroke control device: The turbine is driven to rotate by the vortex rod on the motor gear, causing the small screw rod inside the turbine to move axially. The connecting plate drives the limit rod to move axially accordingly. When the required stroke is reached, the power is cut off by adjusting the limit block to press the stroke switch, and the motor stops running (with the same forward and reverse control)