1、 Structural composition

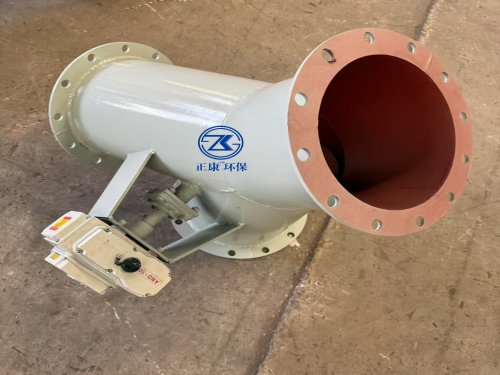

1. Valve body: It usually adopts a steel plate welding structure and is the outer shell of the entire valve, which plays a role in supporting and accommodating other components, and is also connected to the conveying pipeline to form a material conveying channel.

2. Valve shaft: Penetrating the side wall of the valve body, one end is connected to the transmission mechanism, and the other end can be connected to components such as limit detection rods, used to support the valve plate and transmit power, so that the valve plate can swing around its axis.

3. Valve plate: Installed on the valve shaft, located inside the valve body, it controls the flow of materials by swinging, achieving the distribution of materials between different discharge ports. Its shape and size are designed according to different usage requirements and valve body structures.

4. Transmission mechanism: It is generally composed of an electro-hydraulic push rod and a connecting rod. The electro-hydraulic push rod is the power source, which converts electrical energy into mechanical energy and drives the valve shaft to rotate through the connecting rod, thereby achieving the swing of the valve plate. Some parts also have push rod support seats for fixing and supporting the electro-hydraulic push rod.

5. Other components: may also include crank mechanism, travel switch, limit switch, etc. The crank mechanism can convert the linear motion of the electro-hydraulic push rod into the rotational motion of the valve shaft; The travel switch is used to control the range of action of the actuator and confirm the accurate arrival of the valve plate

6. Reservation position: The limit switch can control the opening of the valve plate to meet different material distribution requirements.

2、 Working principle

1. The electro-hydraulic three-way material distribution valve is powered by an electro-hydraulic push rod. After the motor starts, it drives the reducer to rotate, which in turn drives the hydraulic pump to work, allowing hydraulic oil to enter the hydraulic cylinder and push the piston to produce linear reciprocating motion.

2. The movement of the piston drives the valve shaft to rotate through transmission components such as connecting rods or crank mechanisms, thereby causing the valve plate fixedly connected to the valve shaft to swing around the shaft at a determined angle.

By controlling the direction and stroke of the electro-hydraulic push rod, the swing angle and position of the valve plate can be accurately controlled, thereby achieving control over the flow of materials and allowing them to flow out from different discharge ports as needed, achieving the purpose of material distribution.

3、 Product Features

1. Powerful power: Equipped with an electro-hydraulic push rod drive, it can provide a large push and pull force, which can meet the requirements of material transportation and distribution under various working conditions, especially suitable for large-diameter pipelines and high-pressure, high flow material transportation systems.

2. Accurate control: By adjusting the stroke and speed of the electro-hydraulic push rod, the opening of the valve plate and the material flow rate can be accurately controlled, achieving accurate control of the material distribution ratio and meeting the requirements of different production processes.

3. Overload protection: The electro-hydraulic push rod has automatic overload protection performance. When the operation is blocked, the pressure in the oil circuit increases to the set limit, and the overflow valve speed is suitable for accurate overflow. Overload protection is implemented to avoid motor burnout and equipment damage, and to improve the quality and service life of the equipment.

4. Smooth operation: The hydraulic transmission method has the characteristics of smooth transmission and low impact, which makes the swinging process of the valve plate smooth and reduces the impact and agitation on the material, which is conducive to the stable transportation of the material and also reduces the noise during equipment operation.

5. Easy installation: The overall structure is compact, small in size and light in weight, making it easy to install and maintain. It can be directly installed at the fork of the conveying pipeline or at positions where material flow needs to be changed, without the need for additional large installation brackets or foundations.

4、 Application industry

1. Building materials industry: In the transportation process of powdery and granular materials such as cement, lime, sand and gravel, it is used to distribute the materials to different storage warehouses, mixers or conveying equipment, realizing the rational mixing of materials and the automation control of production processes.

2. Metallurgical industry: Suitable for the transportation and distribution of materials such as ore, coke, slag, etc., it can accurately transport materials to different smelting equipment such as blast furnaces, converters, and electric furnaces, or achieve material diversion and direction change in material processing systems, improving production efficiency and quality.

3. Mining industry: Used for crushing, screening, and transportation of ores, the ores can be distributed to different beneficiation equipment or transportation routes according to production needs, achieving ore grading and transportation.

4. Light industry: In industries such as grain processing, feed production, and chemical raw material transportation, various powdered and granular materials can be accurately distributed and reversed to meet the requirements of different production processes for material transportation and distribution.

5. Power industry: In coal-fired power plants, it can be used to distribute coal from the coal conveyor belt to different raw coal bunkers or boilers, and can also be used to process waste such as fly ash, achieving accurate transportation and rational utilization of materials.