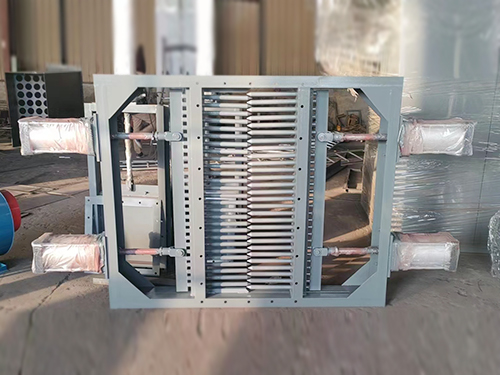

Every product we produce must undergo strict debugging and inspection. The specifications for manual rod valves are as follows:

Good sales, structural composition

Framework: Generally made of welded steel sections, it has the characteristics of good rigidity and no deformation, can support and fix the rod, protect the overall structural stability of the valve, and can withstand the pressure and impact of materials.

Rod: Multiple movable rods are arranged in parallel and inserted into the frame to form an adjustable grid structure. Bars are usually made of steel sections and have strong performance and deformation resistance.

3. Drive device: The rod is directly driven by mechanical devices such as handwheel, push rod or lever, with simple and convenient operation. It can work normally even without electricity or gas source, without relying on electrical or pneumatic systems.

Secondly, the working principle

Material blocking: When all the bars are inserted into the frame, the parallel grid formed can block the block material on one side of the valve, preventing the material from passing through.

2. Material passage: According to the needs of the process flow, one or more rods can be extracted by operating the handwheel, push rod, or lever, and corresponding gaps will appear on the grid plate. The material can enter the other side of the gate through these gaps.

3. Size control: As each rod can be operated separately, the size of the material passing through can be flexibly controlled by increasing or decreasing the number of inserted rods or adjusting the spacing between rods. This is not only applicable to particles or block materials with a diameter of ≤ 50mm, but can also be allowed after adjustment. Using 50mm material.

3、 Characteristics

Easy to operate: Using a single rod operation, each rod can be individually controlled for extraction or insertion, making the operation convenient, flexible, and easy for staff to master and operate.

2. Not easy to block: simple structure. Compared with flat gate valves, it overcomes the disadvantage of large material particles causing high opening and closing forces or even inability to close, allowing for smooth opening and closing and reducing the probability of failure.

3. Long service life: The overall structure is welded with steel sections, which have good rigidity and strength. The bars and frames have good performance and deformation resistance. Under normal usage conditions, it does not require frequent maintenance and has a long service life.

4. Flexible material control: The gap between the bars can be adjusted within a wide range, allowing for accurate control of material throughput and size according to different process requirements, meeting various functional requirements such as screening and feeding.

Fourth, the application industry

Building materials industry: used to control the flow and feeding speed of materials such as cement, sand and gravel during transportation and storage, and to protect the smooth progress of the production process.

2. Mining industry: According to the requirements of mineral processing technology, the particle size and flow rate of block materials such as ore and coal can be accurately controlled to improve mineral processing efficiency.

3. Metallurgical industry: In the processing of materials such as iron ore and coke, manual rod valves are used to control the inflow and outflow of materials, protecting the accuracy of material supply and processing in metallurgical production processes.

Our company adheres to the business philosophy of "daring to explore and innovate". We welcome new and old customers to come and inspect the production and manufacturing of manual rod valve products. We also welcome you to call us for consultation at any time. We look forward to cooperating with you.