Good sales, structural composition

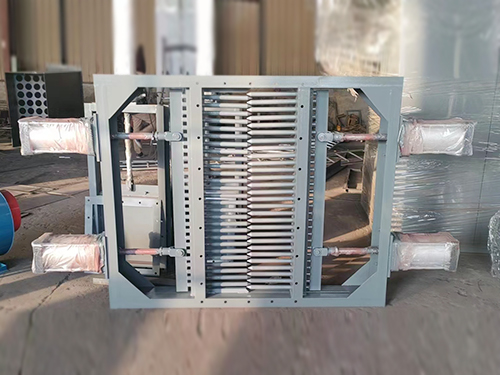

1. Valve body: As the main body of the valve, it is used to connect upstream and downstream pipelines or equipment, providing installation foundation for components such as rods. They are usually made of carbon steel or alloy steel, with sufficient strength and stiffness to withstand the pressure and impact of the material.

Rod: Generally made of round steel, it is a key component for valve opening and closing and material control. Multiple rods are arranged side by side and inserted into the frame to form a parallel grid structure.

3. Pneumatic actuator: mainly a cylinder driven by air pressure signals, which drives the rod to insert or pull out of the frame, achieving the opening and closing of the gate. Usually includes pistons, piston rods, cylinder blocks, etc. It has the advantages of simple structure, fast action, and high thrust.

Framework: Used to fix and support rods, allowing them to be arranged and moved according to a determined pattern, protecting the normal operation of the valve. The frame is usually connected to the valve body, with high precision and stability.

5. Control system: including solenoid valves, air source triplets, etc. Used to control the movement of cylinders, achieve the opening, closing, and adjustment of valves. The control system can control the on/off and magnitude of air pressure by receiving external control signals such as PLC signals or manual operation signals, thereby controlling the movement of the rod.

Secondly, the working principle

Through the control system, the dual pneumatic rod valve sends pressure signals to the actuator, i.e. the cylinder, to propel the overall movement of the rod group. When it is necessary to block materials, the cylinder pushes the rod into the frame, forming a closed grid to prevent materials from passing through; When it is necessary to allow materials to pass through, the cylinder drives the rod to be pulled out, forming a gap through which materials can pass. In addition, by adjusting the number of extraction rods, the size of the material channel can be flexibly controlled to meet the needs of different particle sizes or process flow rates.

feature

1. Suitable speed switch: adopts dual cylinder drive. Compared with single cylinder driven rod valves, it can provide greater driving force, making the insertion and extraction of the rod faster, thus opening and closing the valve at a suitable speed and improving production efficiency.

Good control accuracy: The cylinder stroke and rod extraction quantity can be controlled by the control system to achieve control of material flow and meet the requirements of different processes.

3. Good sealing performance: Sealing structures such as rubber pads or metal rings. It is usually used between bars and between bars and frames to prevent material leakage and protect the sealing performance of valves.

Long service life: The overall structure is welded with steel sections, with good rigidity and no deformation. Components such as bars and frames are made of wear-resistant (based on actual reports) (based on actual reports) materials, which can withstand material erosion and wear, and have a long service life.

Convenient maintenance: The rod is installed in a movable manner, which is easy to disassemble, repair or replace, reducing the operating cost of the system. At the same time, the structure of pneumatic actuators and control systems is relatively simple and easy to maintain.

Thirdly, the application industry

1. Building materials industry: used for conveying and measuring powder and block materials such as cement, lime, gypsum, etc., such as discharge control at the tail of cement kilns and discharge control of raw material warehouses.

Metallurgical industry: used to control the flow rate of materials such as ore, coke, and sintered ore during crushing, screening, and transportation, to ensure the smooth progress of the production process.

3. Mining: Suitable for material conveying systems in various mines such as coal mines and metal mines, such as unloading control and feeding control of belt conveyors. It can control the flow rate and particle size of materials.

Electric power industry: used in power plant coal transportation systems, ash handling systems, etc., to control the transportation and discharge of coal, ash and other materials, and confirm the normal operation of power plants.